40 steam boiler piping diagram pdf

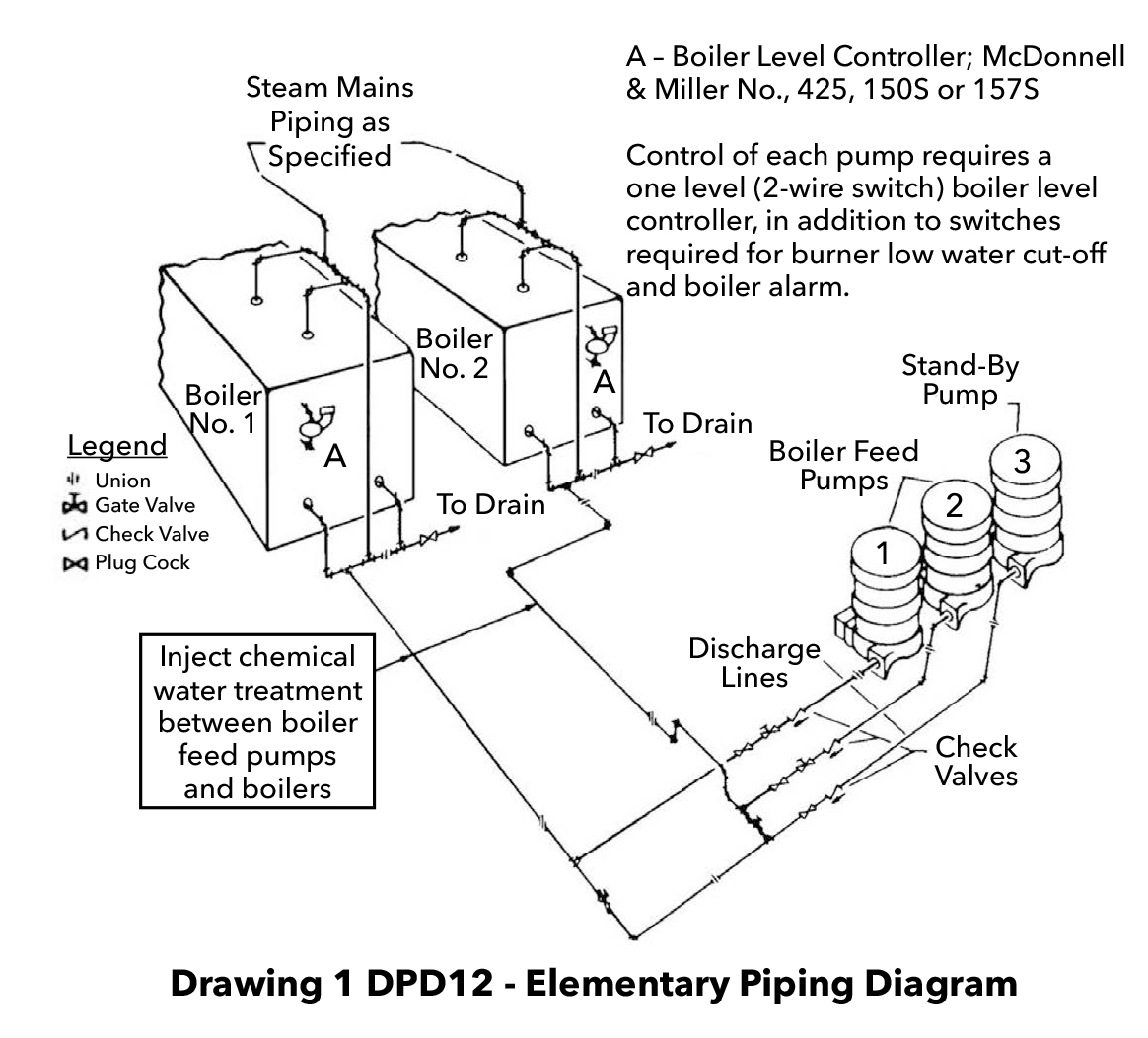

PDF FULL-COLOR TRAINING GUIDE SERIES - PB Heat: Peerless® Boilers SIZING THE BOILER 1. The boiler output must be large enough to satisfy all connected radiators. 2. Size the boiler by doing a radiator count, totaling all of the connected Square Feet. 3. Select a boiler with a Steam Net Load Rating (in square feed of EDR) greater than the total connected radiation. 4. PDF U.S. Department of Veterans Affairs Standard Steam Boiler Plant Piping Diagram Author: Department of Veterans Affairs, Office of Construction and Facilities Management, Facilities Standards Service Subject: Standard Details Created Date: 10/7/2020 2:22:24 PM

PDF Multiple Boiler Piping Diagram - Lochinvar, LLC multiple boiler - primary/secondary piping crest . from system relief valve hot water generator water generator circulator boiler drain (typical) boiler pump (typical) ball valve (typical) air seperator drain port (typical) system circulator to system make up water back flow preventer pressure reducing valve pressure

Steam boiler piping diagram pdf

PDF INSTALLATION AND OPERATION MANUAL - BoilerData.com When opening any drains on the equipment or piping system, steps should be taken to avoid scalding/ burning of personnel due to hot fluids. Whenever possible, the system should be cooled prior to opening any drains. Post these instructions in an appropriate place near the equipment and maintain in good legible condition. WARNING PDF Commercial Boilers & Water Heaters | Patterson-Kelley Commercial Boilers & Water Heaters | Patterson-Kelley PDF Thermodynamic Design of a FireTube Steam Boiler Our engineering team designed a threepass fire tube steam boiler with a capacity of 5000 kg of steam per hour and a operating pressure of 10 bar. The Figure below equations shows a standard three pass fire tube steam boiler system used as a template for our engineering team's design.

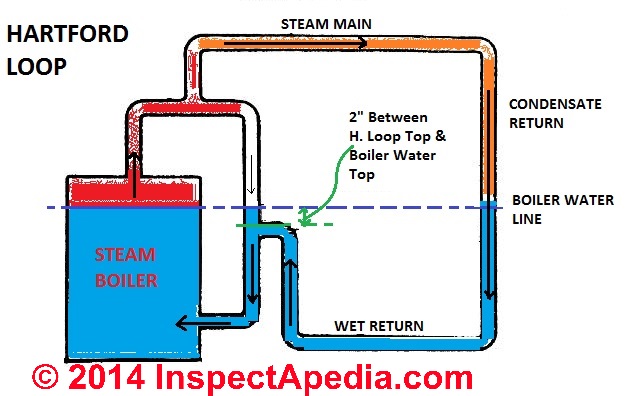

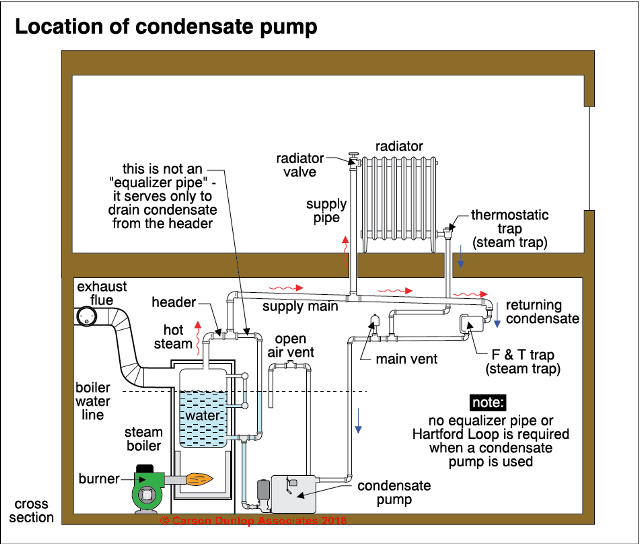

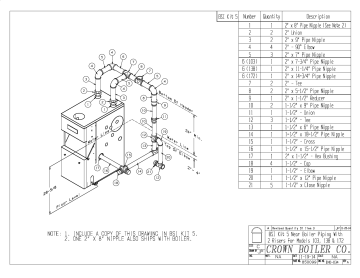

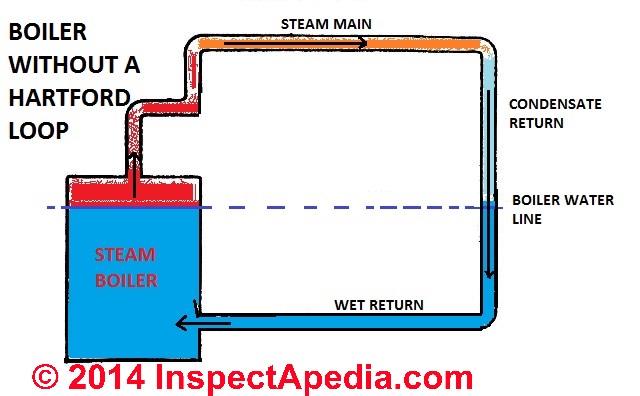

Steam boiler piping diagram pdf. PDF Steam Near Boiler Piping Kits - PB Heat: Peerless® Boilers All near boiler piping including Hartford loop connections Part Number Steam Boiler Model Numbers 63910 63-03L & 63-03 63911 63-04L & 63-04 63912 63-05L Through 64-07 Now Available! Near Boiler Piping Kits for Peerless® Series 63/64™ Gas-Fired Steam Boilers. Save time and money with one complete piping kit. Kits contain PDF ENGINEERING MANUAL Industrial Boilers Referring to the diagram below, the circulation pump has to be sized to the pressure and temperature in the boiler, which can easily be 20 bar and 170°C. Because of this, economisers featuring air-cooled top and bearing flange may be required. PDF Typical Piping for Conventional Single Boiler Installation ... application type diagram see installation manual for complete instructions. install in accordance with all local codes. typical piping for conventional single boiler installation lb-500, lb-750, lb-1000 • safety relief valve setting should not exceed pressure rating of any component in the system. • piping should conform to local codes. PDF Electric Steam Boiler Manual - Vapor Power OR MORE OTHER BOILERS, TWO STOP VALVES ARE REQUIRED BY CODE, ONE OF WHICH SHOULD BE A NON RETURN TYPE, WITH A 1" VENT PLACED IN THE LINE BETWEEN THE TWO VALVES. Steam piping from the boiler to the equipment must be pitched to assure proper drainage of condensate formed in the steam line.

PDF 90,000 BTU's - 105,000 BTU's - Keystoker into equalizer pipe use a close nipple to tie into tee. Condensate return line must be piped in 2" below lowest operating water level. (see diagram pg9). Install a boiler drain valve in the other large opening at bottom of boiler. (See Diagram pg 7). Boiler fill. The boiler fill must be tied into condensate return piping. We recommend using a PDF Multiple Boiler Piping Diagram Full Flow - Lochinvar, LLC multiple boiler - full flow piping crest . relief valve (typical) ball valve (typical) from system boiler drain (typical) y-strainer (recommended) (typical) expansion tank air seperator drain port (typical) system circulator to system make up water back flow preventer pressure reducing valve pressure gauge . PDF STEAM BOILERS - Slantfin VENT PIPING— A. Vent piping installation must be in accordance with ANSI Z223.1-latest edition, National Fuel Gas Code, Part 7, Venting of Equipment. Other local codes may also apply and must be followed. B. Boiler vent pipe must be the full diameter of the boiler draft hood outlet. See dimensions, page 2. If a vent damper is PDF 23 22 13 Steam and Steam Condensate Piping (072913) 1. Piping systems designed for steam pressure below 25 psig are low-pressure steam systems. Piping systems designed for steam pressures from 25 psig up to and including 125 psig are medium-pressure steam. Systems 126 psig and above are high-pressure steam. 2. Distribution piping complying with Thermal Energy Cooperative (TECO) requirements is

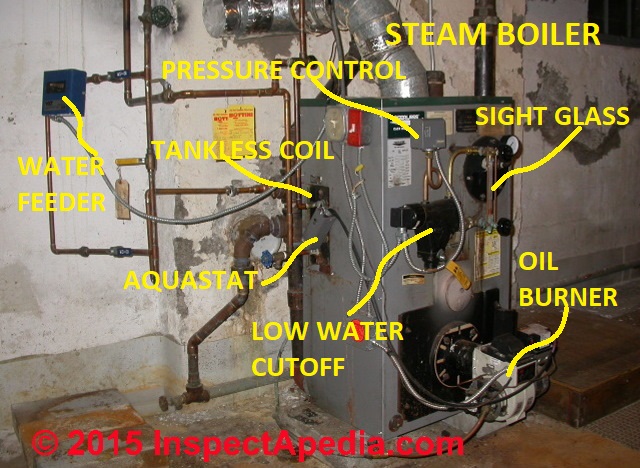

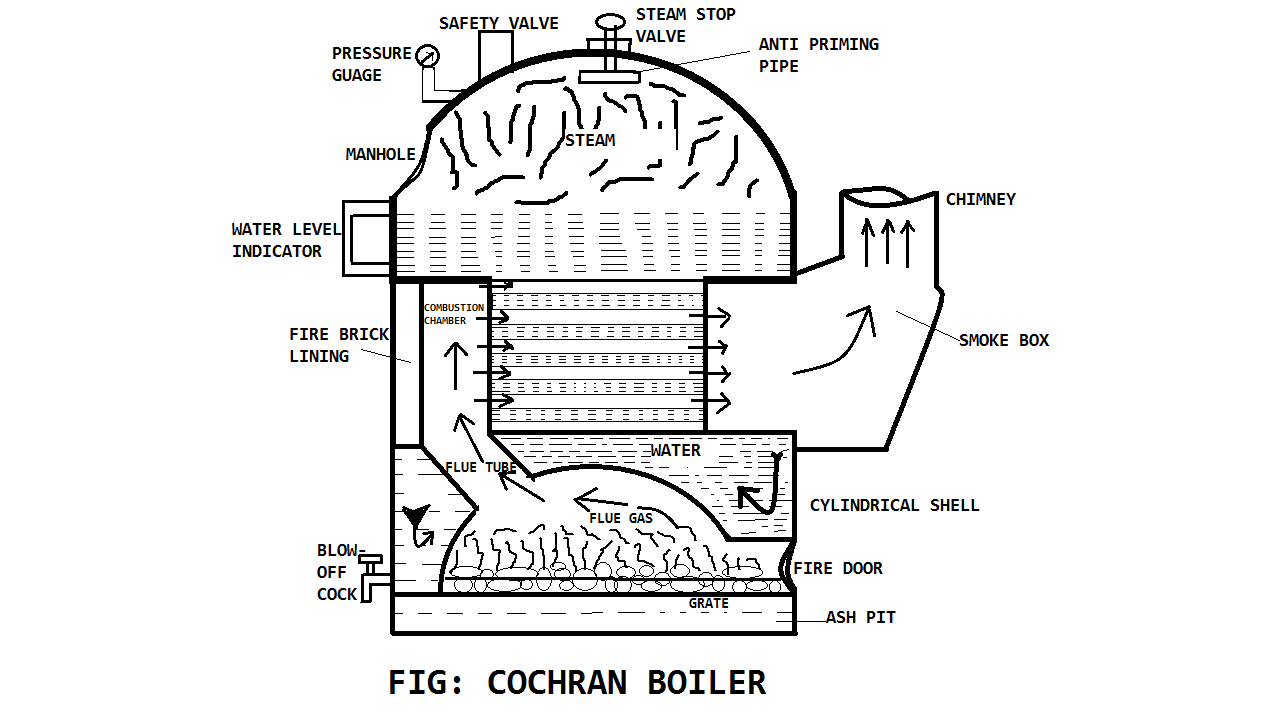

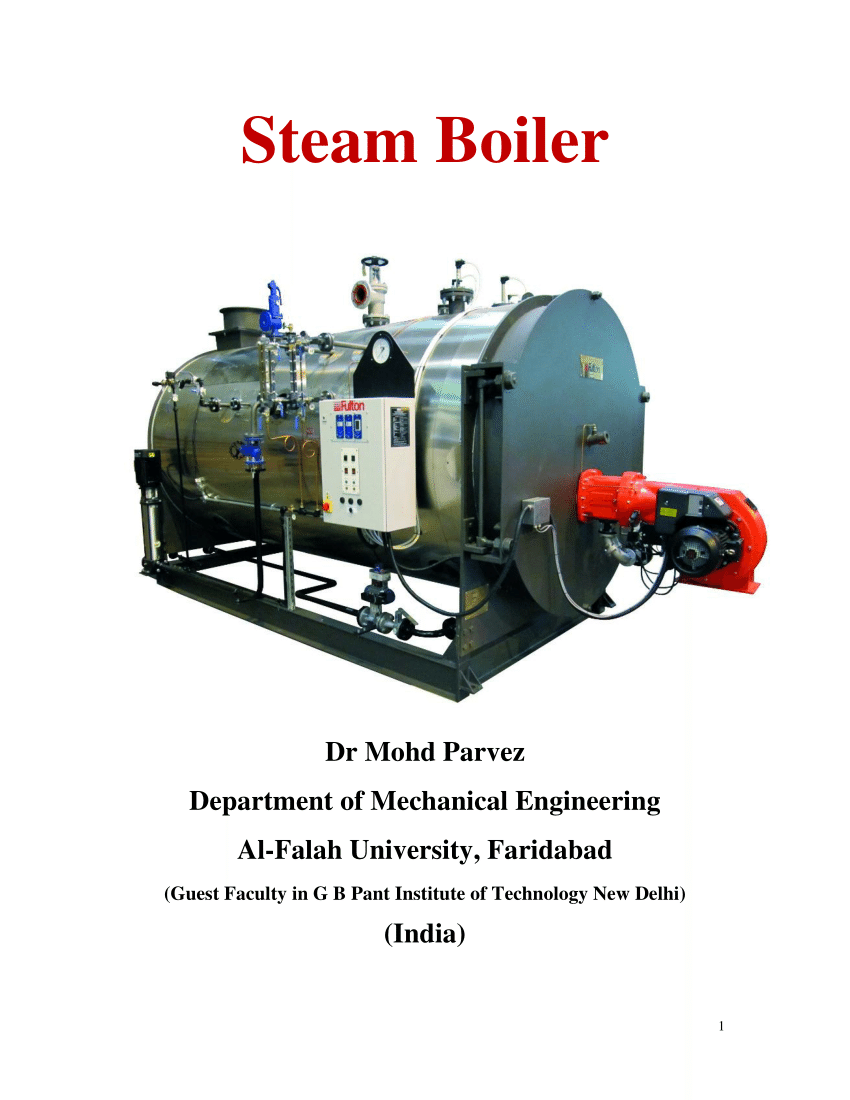

Steam Boiler Diagram With Parts for Dummy's Below is a typical steam boiler diagram for dummy's to understand with name of each component or boiler part. First of all you should understand that there are many types and nomenclature of boilers. For example steam boiler, combi boiler, vaillant boiler, hot water boiler, gas boiler, electric boiler, weil mclain boiler, condensing boiler, oil boiler, burnham boilers, central boiler ... PDF Installation and Operating Service Manual - Bryan Steam piping must be the same size as the relief valve discharge opening. Avoid over-tightening as this can distort valve seats. All piping from relief valve must be independently supported with no weight carried by the valve. 1.4.5 BLOWDOWN CONNECTION Blowdown valve(s) must be full size of the connection on the boiler. Steam boilers 15 psig and PDF I. Piping Diagrams 13. Wire the tank or system/pipe sensor connected to the DHW sensor terminals on the follower boiler addressed as #1. 14. The system/pipe sensor must be placed on common piping to the tank, as close to the tank as possible. 15. The system/pipe sensor is wired to the system sensor terminals on the master boiler. PDF Volume 1, Steam Boilers - Steam, Heating Hot Water, and ... piping diagrams, floor plans, upper level plan of boiler room, mezzanine and pit plans, sections, demolition plans, fuel tank plot plans, and other work as necessary. 2.1.3 Drawings must show plan and elevation views of all valves and equipment which require access and have both North and True North annotated.

PDF Near Boiler Piping - Lochinvar, LLC single boiler - primary/secondary piping crest . hot water generator water generator circulator from system relief valve max expansion tank y-strainer (recommended) ball valve (typical) air seperator drain port (typical) system circulator to system pressure reducing valve back flow preventer pressure gauge make up

PDF System Diagrams - Central Boiler System Diagrams Radiant Heat Multi Zone In-Floor 71 73 75 80 86 102 76 67 65 Forced Air vs. Radiant In-Floor Insulation Closed-cell Polystyrene Thermal Insulation OUT IN Greenhouse Heating Options Radiant PEX piping under the table Forced Air Return Supply When using mesh style tables - PEX piping must be protected from UV rays. 4 mil. black ...

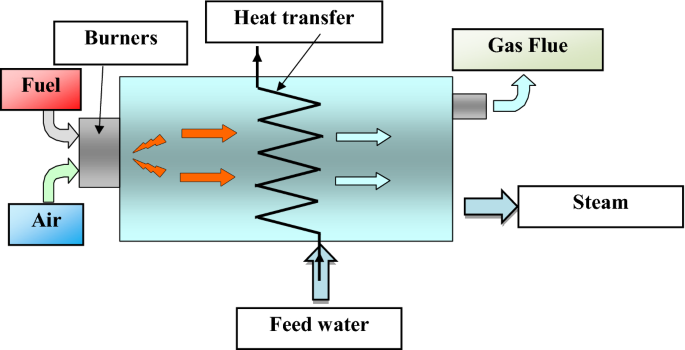

PDF Thermodynamic Design of a FireTube Steam Boiler Our engineering team designed a threepass fire tube steam boiler with a capacity of 5000 kg of steam per hour and a operating pressure of 10 bar. The Figure below equations shows a standard three pass fire tube steam boiler system used as a template for our engineering team's design.

PDF Commercial Boilers & Water Heaters | Patterson-Kelley Commercial Boilers & Water Heaters | Patterson-Kelley

PDF INSTALLATION AND OPERATION MANUAL - BoilerData.com When opening any drains on the equipment or piping system, steps should be taken to avoid scalding/ burning of personnel due to hot fluids. Whenever possible, the system should be cooled prior to opening any drains. Post these instructions in an appropriate place near the equipment and maintain in good legible condition. WARNING

0 Response to "40 steam boiler piping diagram pdf"

Post a Comment