39 open center hydraulic valve diagram

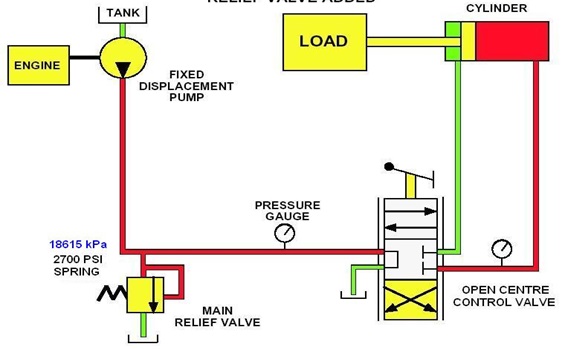

The four ports are marked P, T, A, and B: P is connected to the flow source; T to the tank; and A and B to the respective ports of the work cylinder, hydraulic motor, or some other valve in the circuit. In diagram A, the spool is in such a position that port P is open to port A, and port B is open to port T. Ports A and B are connected to the ... Basic Hydraulic Open Center System Schematic. Open-Center System. In this system, a control-valve spool must be open in the center to allow pump flow to pass through the valve and return to the reservoir. In the illustration below, shows this system in the neutral position. To operate several functions simultaneously, an open-center system must have the correct connections, such as, series, series / parallel connection, and flow divider.

VES Valves PARALLEL HYDRAULIC CIRCUITS OUTLET CONVERSION PORT OPTIONS The most common type of hydraulic circuit is the par-allel circuit. Refer to the parallel circuit diagram. With all valve spools centered, the pump flow will return to tank at low pressure through the open center bypass. When a spool is actuated, the open center bypass is

Open center hydraulic valve diagram

Jun 10, 2016 · P&ID is the acronym for “Piping and instrumentation diagram”, i.e. a very detailed diagram showing the processes happening within a plant, the involved equipment, and their interconnections. A set of standardized P&ID symbols is used … May 24, 2018 · The terms open center and closed center are used to differentiate the two system designs as each describes the construction of the directional control valve as well as the type of hydraulic circuit being used within the system. With an open center system, flow is continuous and pressure is intermittent – which is contrary to a closed center ... Market leading, high performing pneumatic, hydraulic and electric actuators and actuation technologies for valve automation challenges.

Open center hydraulic valve diagram. The purpose of a control valve actuator is to provide the motive force to operate a valve mechanism. Both sliding-stem and rotary control valves enjoy the same selection of actuators: pneumatic, hydraulic, electric motor, and hand (manual). Pneumatic actuators. Pneumatic actuators use air pressure pushing against either a flexible diaphragm or a piston to move a valve mechanism. Hydraulic Kick-out Adjustment - The SH & SHA models have an adjustable single hydraulic kick out preset to 800-1000 psi. The HHA model comes equipped with a double hydraulic kick out preset to 800-1000 psi. To adjust kick-out pressure: Locate jam nut, and set screw on the spool action cap. (Opposite valve's handle) Winch. The diagram shows a winch powered by a hydraulic motor. The directional control valve with built-in relief features optional flow control to control the speed of the winch . The hydraulic pump and motor must be matched to the torque requirements of the winch. Hydraulic and Pneumatic Knowledge Fluid Power Equipment. Basic Hydraulic Open Center Series / Parallel Connection System Schematic. Illustrated below, shows a variation on the series-connected type. Oil from the pump is routed through the control valves in series, as well as in parallel. The valves are sometimes stacked to allow for extra passages.

An open center system is one having fluid flow, but no pressure in the system when the actuating mechanisms are idle. The pump circulates the fluid from the reservoir, through the selector valves, and back to the reservoir. [Figure 2] The open center system may employ any number of subsystems, with a selector valve for each subsystem. 348-9201-707 VA35 NPT Ports 3 Way 3 Position Air . With Power Beyond Main Relief 2500 PSI. Work Port Relief 2000. 14. Inlet DVA35-A440 348-9175-001 Relief Valve DVA35-MRV-2 391-1873-004 Open Loop Circuits: These are circuits where both the inlet to the hydraulic pump and the motor (or valve) return are connected to a hydraulic reservoir. The hydraulic flow from the pressure port on the pump is directed to the device that it is powering and then returned back to the reservoir. selecting a valve hydraulic circuits inlet and outlet covers main system relief valves work sections spool variations spool action options handle-end options specifying gresen sectional body directional control valves contents page no. .10 open center valve assemblies, models v20p, v20t, v20pt and vas features specifications inlet covers

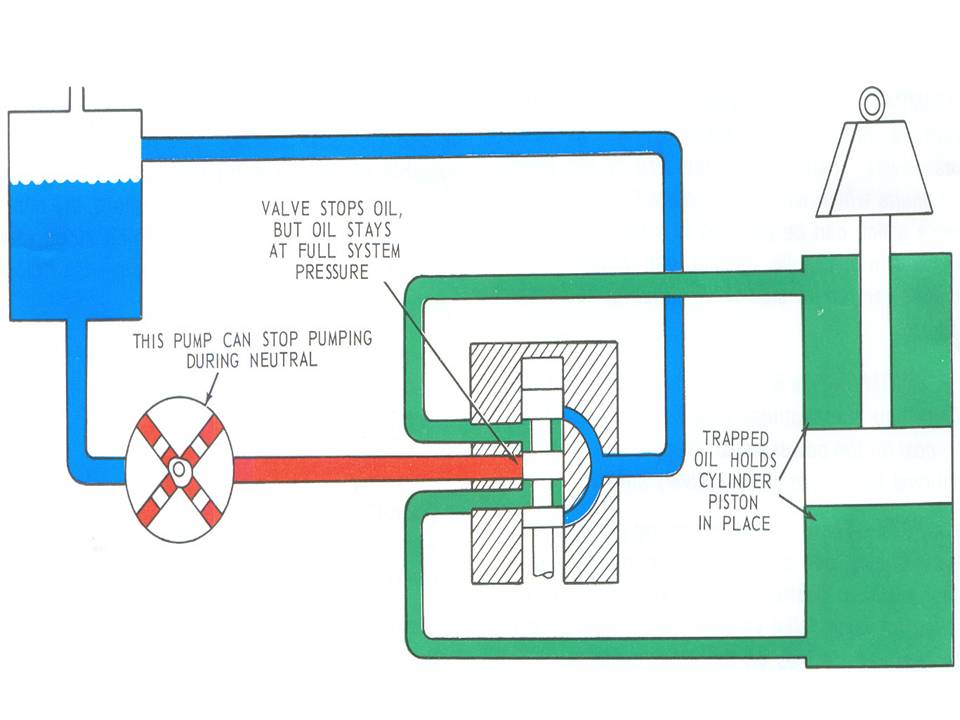

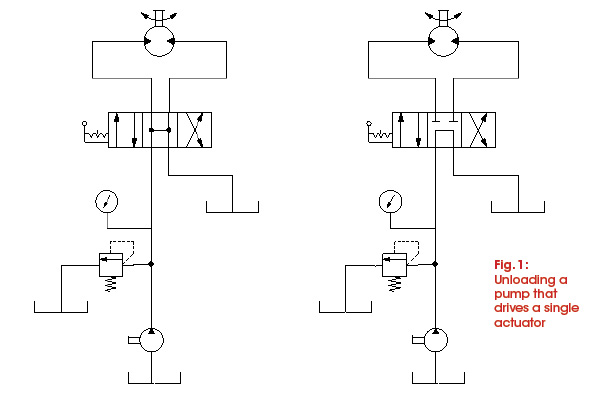

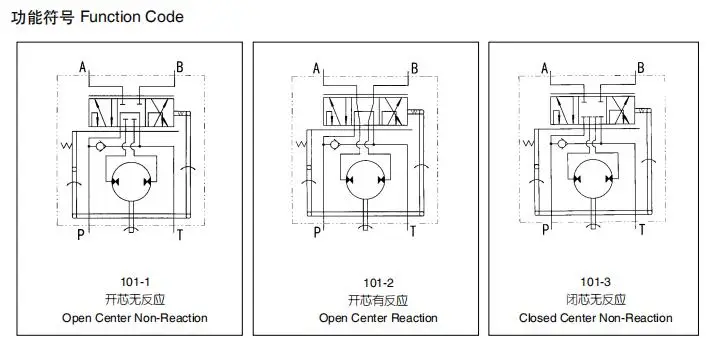

Hydraulic Closed-Center System. In this system, a pump can rest when the oil is not required to operate a function. This means that a control valve is closed in the center, stopping the flow of the oil from the pump. Figure 2-7, shows a closed-center system. To operate several functions simultaneously, a closed-center system have the following ... Hydraulic directional spool valve is a relative motion between the valve spool and valve housing, used for controlling fluid-flow direction of actuator motion (movement), select alternative hydraulic oil control circuits, achieve logic control function. The hydraulic spool valves target is to reach different mechanical movement of actuator ... Screw the relief valve plug (11) back in to the valve body. CAUTION: IF THE RELIEF VALVE IS NOT ADJUSTED TO SPRING SOLID HEIGHT, YOU MAY DAMAGE YOUR HYDRAULIC SYSTEM. 13. The valve is now ready to be used in a closed center hydraulic system * HANDLE BRACKET INCLUDES SCREWS TORQUE MOUNTING SCREWS TO 70-90 IN-LBS. TORQUE MOUNTING SCREWS TO 70-90 ... look here. jd432 hydraulic system diagram - Google Search more info. " Summary The Power Beyond hydraulic system is used as a pressure/flow source for additional functions equipped with independent flow control valves. For example, planter vacuum motors, spray pumps, lift cylinders. Use Power-Beyond when: Tractor SCV control is not needed. Implement control valve requires external load sense ...

Figure 2. Connection of an additional open center DCV using the power beyond facility. Most mobile directional control valves can be made closed center by plugging the drilling between the pressure and tank galleries and leaving the power beyond port plugged (Figure 3). This means that if the existing valve is closed center, supplying pump flow ...

The jack could be air locked. This site says to open the release valve and pump the handle rapidly 10 to 15 times in that case. Here is a link to a document on troubleshooting hydraulic systems, like a jack. If necessary, check to be certain all check valve balls were installed properly. Check for leaks.

Answer (1 of 6): Open Center refers to the open central path of the control valve, when valve is in neutral position. The hydraulic pump is continuous flow type. When valve is neutral then hydraulic fuid goes back to reservoir. As we move valve to (lets say extend actuator side) hydraulic path di...

Hydraulic valves have a tendency to be the most complex components of a hydraulic system, and their schematic symbols are just as complex. ... A 4 port, 3 position, pilot operated, spring returned, open center valve A relief valve A 3 port, 2 position, pilot operated, spring returned valve A 3 port, 2 position, solenoid operated, spring ...

Positions. Most directional control valves are of a spool-type construction. The spool has lands and undercuts, housed within precision-machined casing. As the spool shifts, the lands and undercuts open and close flow paths. The example valve has 3 positions: center, straight through (P to A), and crossover (P to B).

Open center or through center valves need to be connected in series using power beyond porting. Power Beyond allows unused flow to power multiple valve sets downstream. Power beyond also allows the designer to choose which valve sections are more important than another.

What Is A Directional Control Valve And What Are The Types Of Dcv Instrumentation And Control Engineering

Avoid Using Tandem Center Valves in Series. Connecting Multiple Open Center Valves Using Power Beyond. Directional Control Valves - What Every Engineer Should Know. A Quick Guide to the Basics of Hydraulic Relief Valves and Filters. Valve Actuation. All positional valves need to be actuated to perform a function. We will start with mechanical ...

Hi this video explains about the open center hydraulic system.Hydraulic systems are of two types:1. Open center hydraulic system.2. Closed center hydraulic s...

6,596. In common usage a tandem center (open center) valve is simply called "open center". A simple open center valve is called a "Motor valve" as they don't hold the hydraulic pressure in the load lines when in neutral. That allows a motor to continue to spin down and not blow out the line should there not be a cushion valve in the circuit. jb.

Operation of the system following actuation of the component depends on the type of selector valve being used. Figure 12-5: Basic open-center hydraulic system. Several types of selector valves are used in conjunction with the open-center system. One type is both manually engaged and manually disengaged.

China Hydraulic Rotary Diverter Valve 3 Way Open Center 24 Gpm 8 Sae Ports China Rotary Diverter Valve Hydraulic Rotary Diverter Valves

Hydraulic Open-Center System. In this system, a control-valve spool must be open in the center to allow pump flow to pass through the valve and return to the reservoir. Figure 2-3, shows this system in the neutral position. To operate several functions simultaneously, an open-center system must have the correct connections, which are discussed below.

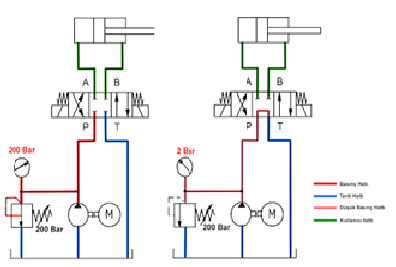

Open and closed center hydraulic systems Open center Closed center Section 2 PRIME MOVER ..... 6 Power take-offs Engine crankshaft driven Auxiliary engines Belt driven pumps ... Relief pressure is the pressure at which the system relief valve will open and bleed flow back to the reservoir until the system pressure diminishes. Typically, the ...

Open center hydraulics allow the oil to pass through the control valve when the valve is in the neutral position. A closed center valve shuts off the flow through the valve unless it is in a demand position. Using a closed center control valve on an open center system will force the relief valve to open to bypass oil when the valve is in the ...

Hydraulic Directional Control, BA series valve is a 3-position, 4-way valve in 1,2 or 3 spool versions with float available. 12-volt solenoid 3-position, 4-way. For full functionality of this site it is necessary to enable JavaScript .

Directional Control Valves Open Center Sliding Spool Directional Control Valve Hydraulic Schematic Troubleshooting

Description. The 4-Way Directional Valve block represents a directional control valve with four ports and three positions, or flow paths. The ports connect to what in a typical model are a hydraulic pump (port P), a storage tank (port T), and a double-acting actuator (ports A and B).Fluid can flow from the pump to the actuator via path P-A or P-B and from the actuator to the tank via path A-T ...

http://http://www.mekanizmalar.com/menu_pneumatic.htmlThis video explains the working principles of an open center spool valve.

Market leading, high performing pneumatic, hydraulic and electric actuators and actuation technologies for valve automation challenges.

May 24, 2018 · The terms open center and closed center are used to differentiate the two system designs as each describes the construction of the directional control valve as well as the type of hydraulic circuit being used within the system. With an open center system, flow is continuous and pressure is intermittent – which is contrary to a closed center ...

Hydraulic Circuits Hydraulic Closed Center System Using Variable Displacement Pump Hydraulic Schematic Troubleshooting

Jun 10, 2016 · P&ID is the acronym for “Piping and instrumentation diagram”, i.e. a very detailed diagram showing the processes happening within a plant, the involved equipment, and their interconnections. A set of standardized P&ID symbols is used …

0 Response to "39 open center hydraulic valve diagram"

Post a Comment