35 al-si phase diagram

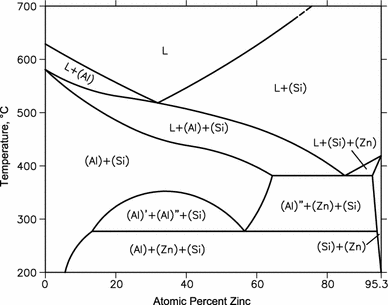

Phase Diagram Resources from ASM International. Alloy phase diagrams and crystal structure data are used by metallurgists, materials engineers, and materials scientists to develop new alloys for specific applications; fabricate these alloys into useful configurations; design and control heat treatment procedures for alloys that will produce the required mechanical, physical, and chemical ... The Al-Si phase diagram, a diagram of considerable commercial significance, is the starting point for developing more complex alloys and for understanding their behavior. Si is a common impurity in aluminum alloys, but it is also a deliberate alloying addition in both cast and wrought Al alloys.

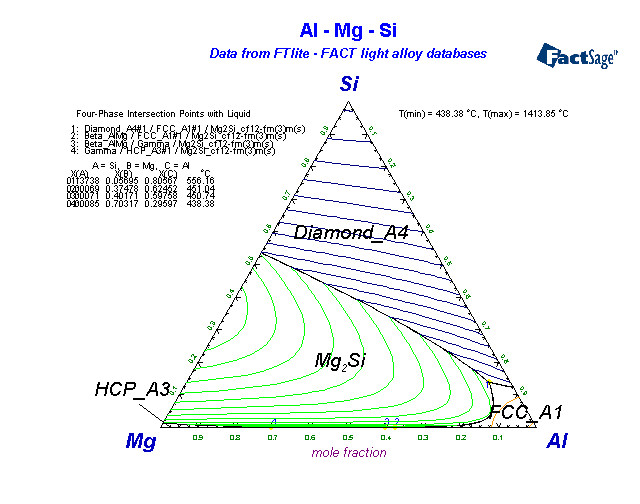

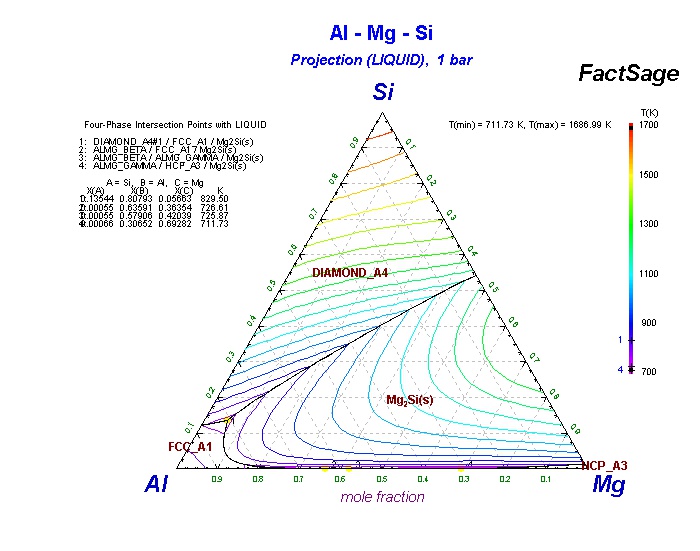

2.1. Al-Mg-Si PHASE DIAGRAM The Al-Mg-Si phase diagram can be used for the analysis of many wrought alloys of 6XXX series and casting alloys of the 356.0 type, provided the concentration of iron impurity is low (Table 2.1). This diagram is also the basic diagram for casting alloys of the 512.0 type that are considered in Chapter 4.

Al-si phase diagram

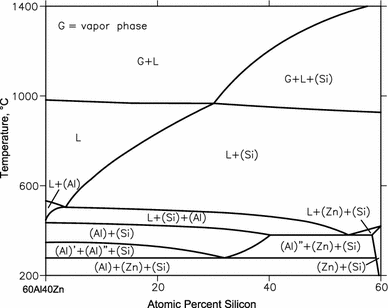

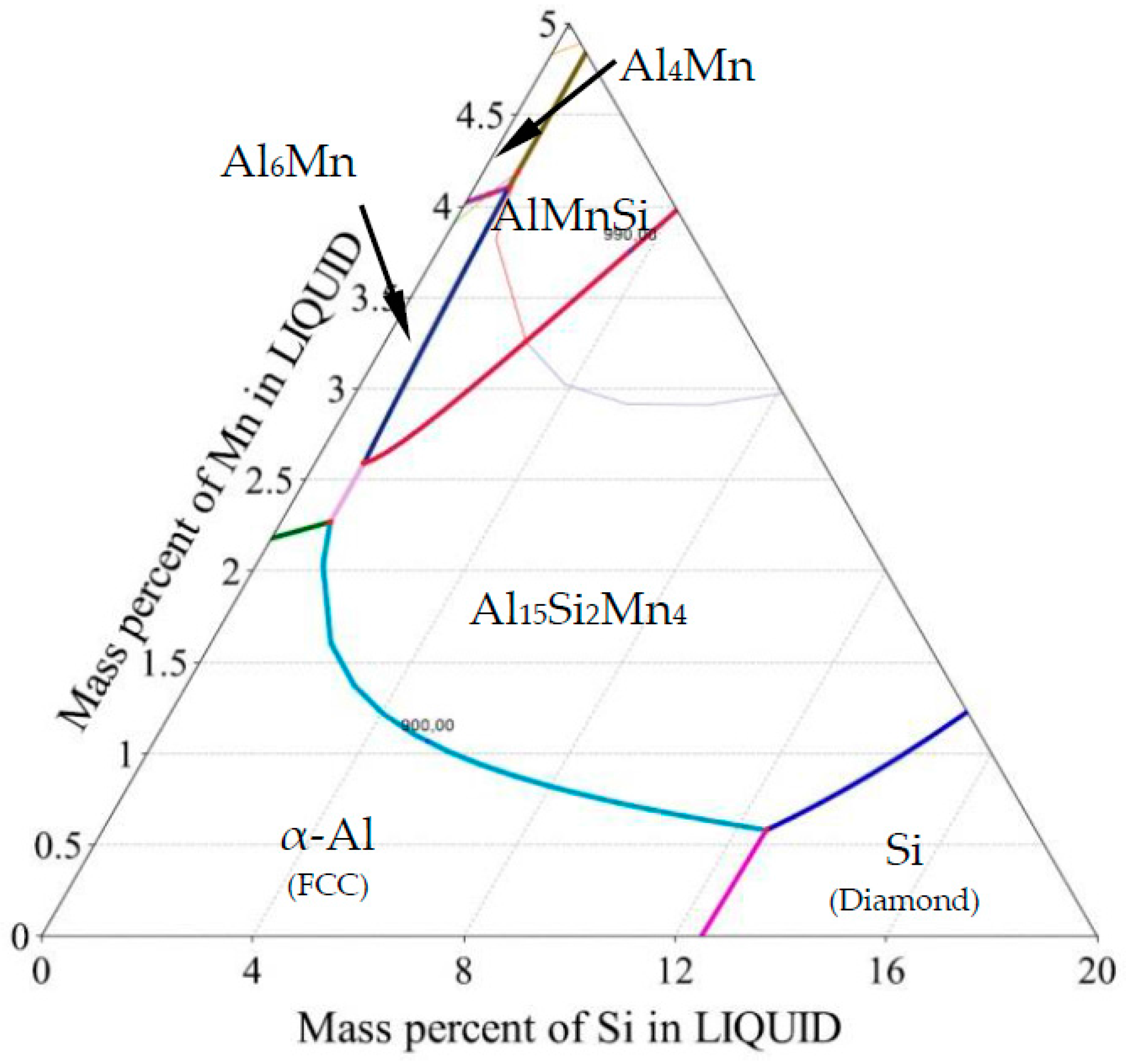

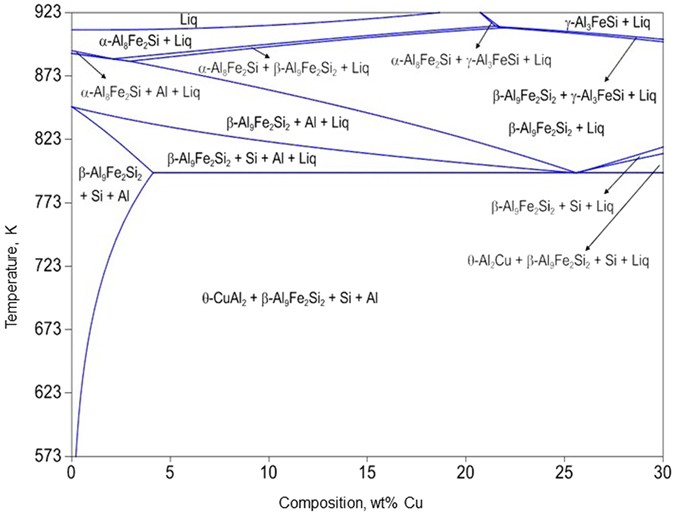

Aluminum-Magnesium-Silicon Ternary Alloy Phase Diagram. Ternary isothermal diagram ( 427°C), crystal data, melting points. D.Ludecke, (1986) Phase Diagram and Thermochemistry of the Al-Mg-Si System, Z. Metallkde., 77 278-283. To apply the basic concepts of phase diagrams to binary aluminium alloys. To extend the discussion to an outline of ternary phase diagrams, and to show how a so-called pseudo-binary section can be applied with benefit to the Al-Mg-Si system for alloys balanced in Mg2Si. Date of Issue: 1999 EAA - European Aluminium Association the phase composition of casting Al-Si alloys of the 4XX.0 series. In many cases, this quaternary diagram solely makes it possible to answer the question as to which Fe-containing phases can be formed in a particular commercial alloy. 1.1. Al-Fe-Si PHASE DIAGRAM The Al-Fe-Si system is the basic system for the structure analysis of commercial

Al-si phase diagram. system, the phase diagram usually has the general appearance of that shown in Fig. 3. The diagram consists of two single-phase fields separated by a two-phase field. The boundary between the liquid field and the two-phase field in Fig. 3 is called the liquidus; that between the two-phase field and solid field is the solidus. 34Mat: K. Matsuyama, "Ternary Diagram of Al-Cu-Si System",Kinzoku No Kenkyu, 11, 461-490 (1934) in Japanese. (Equi Diagram; Experimental) (Equi Diagram; Experimental) Google Scholar Eutectic Phase Diagram of Al-Si Analysis. Ask Question Asked 2 years, 7 months ago. Active 2 years, 7 months ago. Viewed 1k times 0 $\begingroup$ Hello, How can I know from this phase diagram: 1. The composition of the alloy Al-Si that allows precipitation to occure? 2. The range of temperatures where the Al-Si is soluble? Title Phase Diagram and Thermochemistry of the Al-Mg-Si System Publication Z. Metallkd. Language English Authors Lüdecke D., Aachen RWTH University, Lehrstuhl für Metallurgie der Kernbrennstoffe und Theoretische Hüttenkunde, Aachen, Germany Original diagram Al-Mg-Si isothermal section at 427 °C

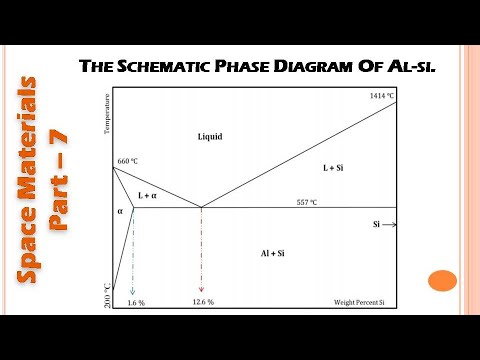

Phase Diagrams • Indicate phases as function of T, Co, and P. • For this course:-binary systems: just 2 components.-independent variables: T and Co (P = 1 atm is almost always used). • Phase Diagram for Cu-Ni system Adapted from Fig. 9.3(a), Callister 7e. (Fig. 9.3(a) is adapted from Phase Diagrams of Binary Nickel Alloys , P. Nash The Al-Si phase diagram is a straightforward, classic example of a eutectic system where each element has little, if any solubility in the other. Aluminum melts at 660.452 °C while silicon melts at 1414 °C. The diagram, from Murray and McAlister (Vol. 8, Metals Handbook, 8th ed., 1973, p. 263), shows the eutectic at 12.6 wt. % Si Transcribed image text: Referring to the phase diagram of aluminium (Al) and silicon (Si) alloy. The overall composition of silicon is 70 % by weight at room temperature. The alloy is being heated, a. Find the temperature in degree Celsius at which the alloy starts to melt. b. Find the compositions of the liquid and solid respectively at the temper- ature just above the temperature found in ... The copper is used for precipitation hardening (Al 2 Cu, Al 5 Mg 8 Cu 2 6), should that be necessary.Iron is to be avoided if possible, since it can form plate-like precipitates (Al 5 FeSi) which embrittle the casting and can block the flow of liquid metal in the mould. The strontium, when added delibrately, helps to modify the shape of the silicon, rather as does sodium.

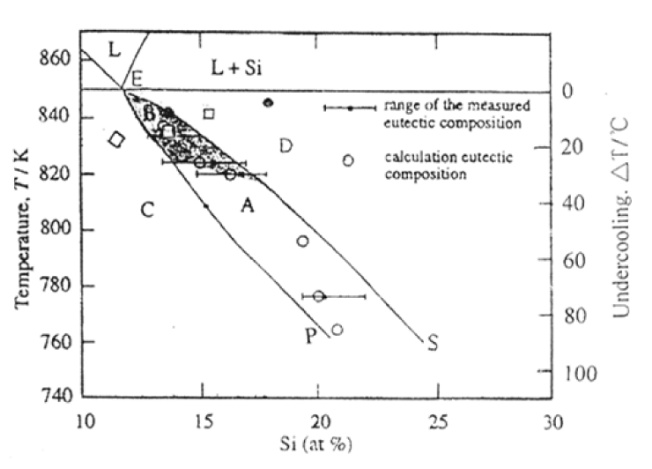

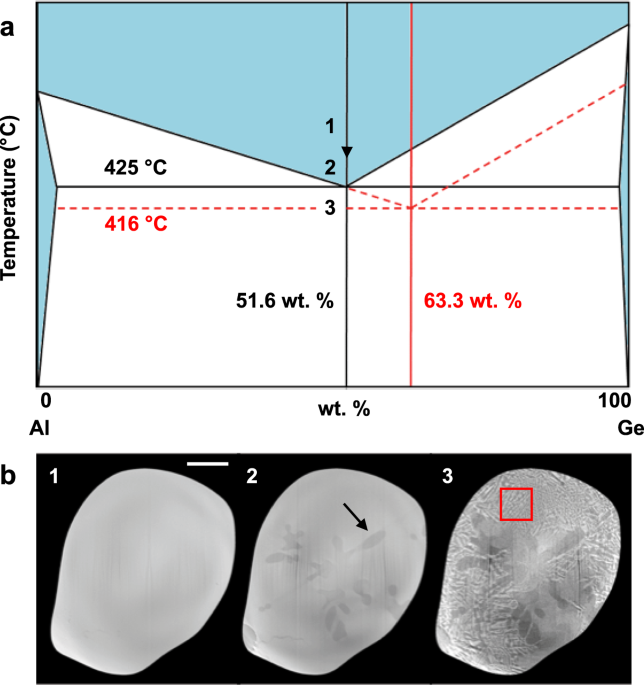

Si/Al Phase Diagram Most Si/Al alloys are cast near this eutectic point, they are cheap to manufacture; but cuboid Si flakes cause brittleness. Doping with 0.01% Na alters the compositional and temperature of the eutectic point (red lines): Alloy 2, which has the same relative amounts of Si and Al, now preciptates in a hypoeutectic fashion. The binary Al-Si phase diagram was initially studied by Fraenkel of Germany in 1908. It is a relatively simple binary diagram where there is very little solubility at room temperature for Si in Al ... The Al-Si Phase Diagram - Volume 15 Issue S2. To send this article to your Kindle, first ensure no-reply@cambridge.org is added to your Approved Personal Document E-mail List under your Personal Document Settings on the Manage Your Content and Devices page of your Amazon account. The Al-Si Phase Diagram. Metallographic Assessment of Al-12Si High-Pressure Die Casting Escalator Steps. Color Metallography and Electron Microscopy Techniques Applied to the Characterization of 413.0 Aluminum Alloys. Structure characterization and precipitation in two Al-Mg-Si-Mn casting alloys.

Phase diagrams under pressure of Al-Si and Al-Ge systems. By Lindeman's melting law 7, 8 and using the concentration-dependent mean-square displacement 〈 u2 〉 x in , for the Al 1−x Si x and Al 1−x Ge x alloy systems, we define Lindeman's criterion for melting, Xm ( x ), of these alloys as the ratio of two times the root-mean-square ...

Abstract. Preliminary experiments and phase diagram calculations were conducted to determine the equilibrium phase diagram of the Al-Mg 2 Si pseudobinary section. It was found that there is a narrow ternary phase field of Al+Mg 2 Si+liquid in the diagram. At the pseudoeutectic composition of Al-13.9 wt-%Mg 2 Si, a pseudoeutectic reaction takes place between the temperatures of 583.5 and ...

The Al-Si Phase Diagram. The binary Al-Si phase diagram was initially studied by. Fraenkel of Germany in 1908. It is a relatively simple . binary diagram where there is very little solubility at room.

Al-Ba-O-Si_Al2O3-BaO-SiO2_Liquidus-projection FToxid: Al-Ba-O-Si_Ba2Si3O8-BaAl2Si2O8 FToxid: Al-Ba-O-Si_Ba5Si8O21-BaAl2Si2O8 FToxid: Al-Ba-O-Si_BaAl2Si2O8-Al(1.3)Si(0.35)O(2.65) FToxid: Al-Ba-O-Si_BaAl2Si2O8-Al2O3 FToxid: Al-Ba-O-Si_BaO-SiO2-Al2O3_1400C FToxid: Al-Ba-O-Si_BaSi2O5-BaAl2Si2O8 FToxid: Al-Ba-O-Si_SiO2-BaAl2Si2O8 FToxid: Al-Ba-O-Sr ...

The dark region in between the plates is the (Al) solid solution crystallized from the remaining liquid. The composition of the τ 2 phase is close to Fe 2 Al 5 Si 2 as shown in Table 1a and corresponds to the K phase (Fe 22 Al 63-52 Si 15-26) of Murav'eva et al. and Zarechnyuk et al. and K 2 phase (Fe 6 Al 12 Si 5) reported by Takeda and ...

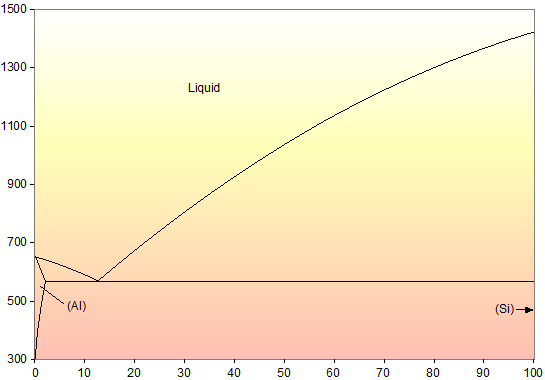

The Al-Si phase diagram is the base component system for the Al-Si series of alloys. As Figure 1 shows, it is a binary eutectic type phase diagram with limited aluminum and silicon solubility. The melting temperature of pure aluminum is 660°C. The solubility of silicon in the aluminum melt reaches a maximum of 1.6 wt.% at the 577°C eutectic ...

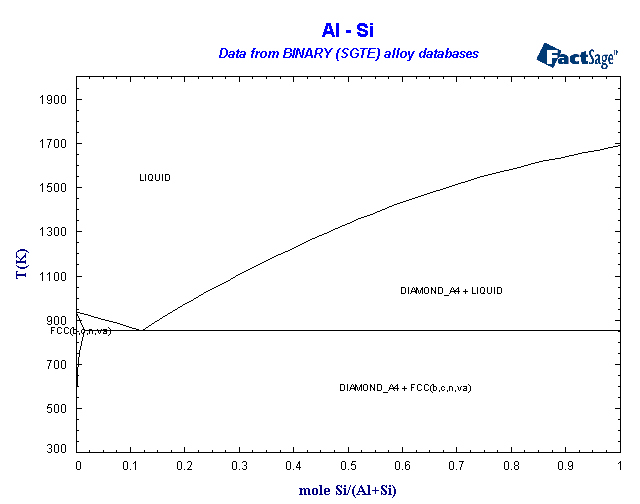

The phase diagram contains two solid solution phases (α-Al) (FCC_Al) and diamond cubic Si (Diamond-A4), a liquid phase, and three mixed phases; FCC_Al + Diamond-A4, liquid + FCC_Al, and liquid + Diamond A4. The melting points of Al and Si are 932.77 and 1687.73 K (659.62 and 1414.58 °C), respectively. From the phase diagram, the eutectic ...

Figure 2 From The Influence Of Copper On An Al Si Mg Alloy A356 Microstructure And Mechanical Properties Semantic Scholar

Al-Si-Cu(-Mg) alloys dominate the market for power train components such as engine blocks, cylinder heads, pistons, and die castings where strength at temperature and/or wear resistance is more important than ductility. Schematic Al-Si phase diagram showing the composition ranges for the most common foundry alloys

Direct Electrolytic Al Si Alloys Deasa An Undercooled Alloy Self Modified Structure And Mechanical Properties Intechopen

Al-Si diagram is a eutectic diagram where solid solubility at least of aluminium in silicon is negligible, and maximum solubility of silicon in aluminium (at eutectic temperature) is 1.65%. The eutectic composition is 12.7% silicon. Fig. 3.18 illustrates this diagram and photomicrographs of alloys at room temperature.

2. Mg-Al (Magnesium-Aluminium) This is the most important Mg binary phase diagram because Al is added to mg in most of the commercial types of Mg alloys. Several researchers [ 81 - 95] studied the liquidus, solidus, and solvus lines of the Mg-Al system.

Al-Si alloys differ from our "standard" phase diagram in that aluminium has zero solid solubility in silicon at any temperature. This means that there is no beta phase and so this phase is "replaced" by pure silicon (you can think of it as a beta phase which consists only of silicon).. So, for Al-Si alloys, the eutectic composition is a structure of alpha+Si rather than alpha+beta.

The Al-Si Phase Diagram The binary Al-Si phase diagram was initially studied by Fraenkel of Germany in 1908. It is a relatively simple binary diagram where there is very little solubility at room temperature for Si in Al and for Al in Si. Thus, the terminal solid solutions are nearly pure Al and Si under equilibrium conditions.

Experimental Study Of The Phase Equilibria In The R Al Si Ternary Systems R Rare Earth Element The Ho Al Si Isothermal Section At 500 C

the phase composition of casting Al-Si alloys of the 4XX.0 series. In many cases, this quaternary diagram solely makes it possible to answer the question as to which Fe-containing phases can be formed in a particular commercial alloy. 1.1. Al-Fe-Si PHASE DIAGRAM The Al-Fe-Si system is the basic system for the structure analysis of commercial

To apply the basic concepts of phase diagrams to binary aluminium alloys. To extend the discussion to an outline of ternary phase diagrams, and to show how a so-called pseudo-binary section can be applied with benefit to the Al-Mg-Si system for alloys balanced in Mg2Si. Date of Issue: 1999 EAA - European Aluminium Association

Aluminum-Magnesium-Silicon Ternary Alloy Phase Diagram. Ternary isothermal diagram ( 427°C), crystal data, melting points. D.Ludecke, (1986) Phase Diagram and Thermochemistry of the Al-Mg-Si System, Z. Metallkde., 77 278-283.

Figure 1 Calculation Of Liquidus Temperature For Aluminum And Magnesium Alloys Applying Method Of Equivalency

Thermodynamic Investigation On Phase Formation In The Al Si Rich Region Of Al Si Ti System Sciencedirect

Calorimetric Measurements And Assessment Of The Binary Cu Si And Ternary Al Cu Si Phase Diagrams Sciencedirect

Binary Phase Diagrams And Thermodynamic Properties Of Silicon And Essential Doping Elements Al As B Bi Ga In N P Sb And Tl Abstract Europe Pmc

0 Response to "35 al-si phase diagram"

Post a Comment